High-frequency quick quenching and tempering provide the following advantages on IT Wire.

- Fine and uniform grain structure and uniform mechanical properties along the total length.

- No Decarburization through the process.

- High performance for cold forming.

- Can be formed into springs with high fatigue life, low setting loss, and stability.

IT Wire is a high-strength steel spring wire in accordance with JIS G 3560 and JASO (Japan Automobile Standard Organization's Standard) C605-80, ASTM A1000, A401,A229.

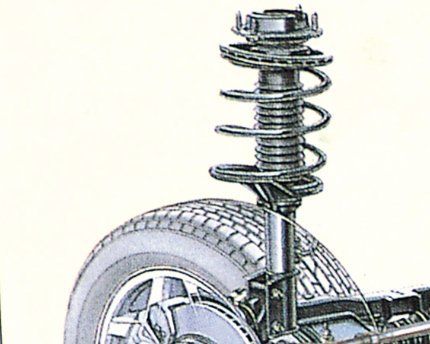

The wire is widely used for general industrial springs, including suspensions in two- and four-wheel vehicles.

The wire is widely used for general industrial springs, including suspensions in two- and four-wheel vehicles.

| ITW Spec | Final Products Diameter 7.00~17.00mm (0.275~0.670 inch) | |||

| Grade Symbol | Tensile Strength | Reduction of Area | Roundness | Tolerance |

| SWI-170 | 1,650~1,750 MPa(240~254 ksi) | Min.35% | 0.050mm or less | ±0.050mm |

| SWI-180 | 1,750~1,850 MPa(254~270 ksi) | Min.35% | 0.050mm or less | ±0.050mm |

| SWI-190 | 1,850~1,950 MPa (270~283 ksi | Min.35% | 0.050mm or less | ±0.050mm |

| SWI-200 | 1,950~2,050 MPa (283~296 ksi) | Min.35% | 0.050mm or less | ±0.050mm |

Other tensile strength range than above standard is applicable.

Available upon consultation of special specifications.